We work with organizations that rely on validated skills data to make operations effective, efficient, and safe.

"Our scheduling and dispatching processes are more efficient, we are improving the quality of work performed for customers, and our employees can own their development with an understanding of specific training needs."

"Kahuna helps manage the competency of our employees to ensure we are compliant with the regulatory requirements of our business. It provides a robust system to assess our employees against the standards within their jobs.

"The biggest advantage for our teams besides "about to expire" notifications and avoiding penalties from authorities, is the analytic and reports function. It's a great tool for our managers to have an overview of their departments and plan ahead."

Frequently Asked Questions About Manufacturing Skills Management

What is manufacturing skills and competency management?

Manufacturing skills and competency management is the business process of identifying critical skills, assessing organizational capability, and developing the workforce to meet dynamic industry demands and strategic business goals.

What are the benefits of skills and competency management in manufacturing?

Manufacturing skills management enables manufacturing organizations to meet fluctuating demand for talent, reduce and control cost of poor quality, minimize the threats of future disruptions, diminish risk and impacts associated with HSE incidents, and mitigate non-compliance risk.

What is effective training in manufacturing?

Effective training gives employees the knowledge, skills, experiences, and capabilities they need to perform their roles efficiently and in line with safety and quality standards.

How does skills management enable effective training?

Skills and competency management provides validated skills data to employees and managers at every level in the organization, from the factory floor to the C-Suite. These skill insights enable leaders to:

- Analyze and understand workforce skill gaps.

- Ensure a sufficient supply of qualified trainers.

- Access readily available training materials.

- Verify the knowledge and experience of employees.

- Plan for current and future disruptions with qualified and skilled teams.

What is Industry 4.0 or smart manufacturing?

Industry.4.0, also called smart manufacturing, is the advancement of technology and digital transformations within manufacturing. These advancements impact manufacturing processes and procedures, quality metrics, workforce skills, training and development needs, and more.

What are the benefits of Industry 4.0 in manufacturing?

Benefits of Industry 4.0 and smart manufacturing include:

- Higher efficiency and productivity with more streamlined supply chain operations, and seamless communication between digital systems and the personnel operating them.

- Better flexibility and agility through improved organizational and workforce capabilities, and competitive advantage.

- Increased profitability and lower costs associated with trade, transportation, and logistics, and new market growth opportunities.

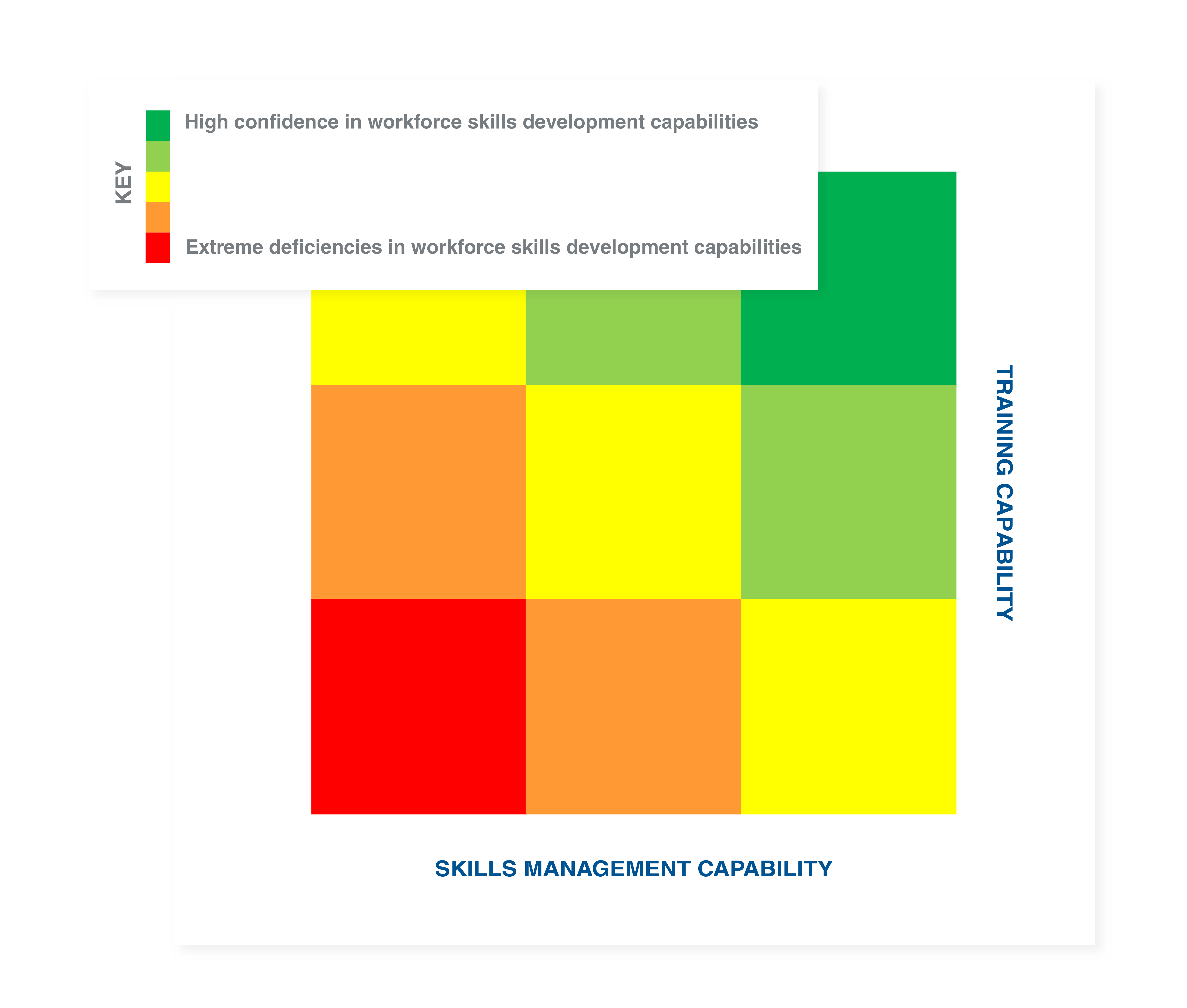

Skills & Training Capability Matrix

Download our Skills & Training Capability Readiness Matrix to help you assess your organization's ability to support consistent, effective training and skills management on the plant floor.