Manufacturing Skills Management

Manufacturing organizations are operating under increasing pressures due to supply chain disruptions, technology advancements, skill and talent shortages, and changing consumer preferences. Establishing organizational resiliency is key in this dynamic smart manufacturing environment. Resiliency begins with a comprehensive understanding of workforce skills and capability.

WEBINAR ON-DEMAND

Driving Digital Transformation with a Skilled Frontline Workforce

Join the Manufacturing Millennial, Stanley Black & Decker, and Kahuna Workforce Solutions as we dive into how manufacturers are leveraging skills data to:

- Drive value for smart manufacturing and digital transformation initiatives.

- Understand skills gaps and train more effectively.

- Engage and retain a new generation of manufacturers in the workforce.

- Reach organizational goals and achieve operational efficiency.

Watch Now

Resources to Develop Standardized Manufacturing Skills Assessments

Skills Matrix Guide & Template

Develop, prioritize, standardize, and digitize a comprehensive skills framework that fully meets the needs of your business and helps your organization achieve better operational outcomes.

Operational Skills Management Report

Learn why operational skills management is an essential business imperative for organizations striving to stay competitive and adaptable in the dynamic manufacturing industry.

Workforce Knowledge, Skills, and Abilities

KSAs differentiate how members of the workforce will perform tasks, actions, or job responsibilities. Collectively, KSAs indicate how the workforce will execute job functions and meet operational demands.

DEMO ON-DEMAND

How Does Skills Management Support Manufacturing Operations?

Manufacturers are navigating a complex landscape with workforce shortages, supply chain disruptions, and advancing technology. Agility is essential to maintaining operations and increasing efficiency and productivity.

In these three short videos, we'll explore how Kahuna's validated skills data enables a more agile workforce and robust manufacturing processes:

- Episode 1: Safety and Compliance

- Episode 2: Training and Employee Retention

- Episode 3: Scheduling and Deployment

Watch Now

WEBINAR ON-DEMANDClosing the Skills Gap: Tech Solutions for Today’s Skill Shortages

Join Kahuna and Deephow as we discuss how integrated skills management and video training technologies address critical skills gaps in manufacturing, enhance workforce resilience, boost employee engagement, and ensure operational safety.

WEBINAR ON-DEMANDThe Promises of Smart Manufacturing: Pipe Dream or Reality?

Research shows that more than 85% of companies are unable to achieve successful smart manufacturing deployments. Join Kahuna and NxGen Group as we discuss what smart manufacturing really is; where the failure point often occurs; how validated skills data and training can provide critical insights; and why the right mix of people, processes, and technology is essential in making smart manufacturing a reality for the business.

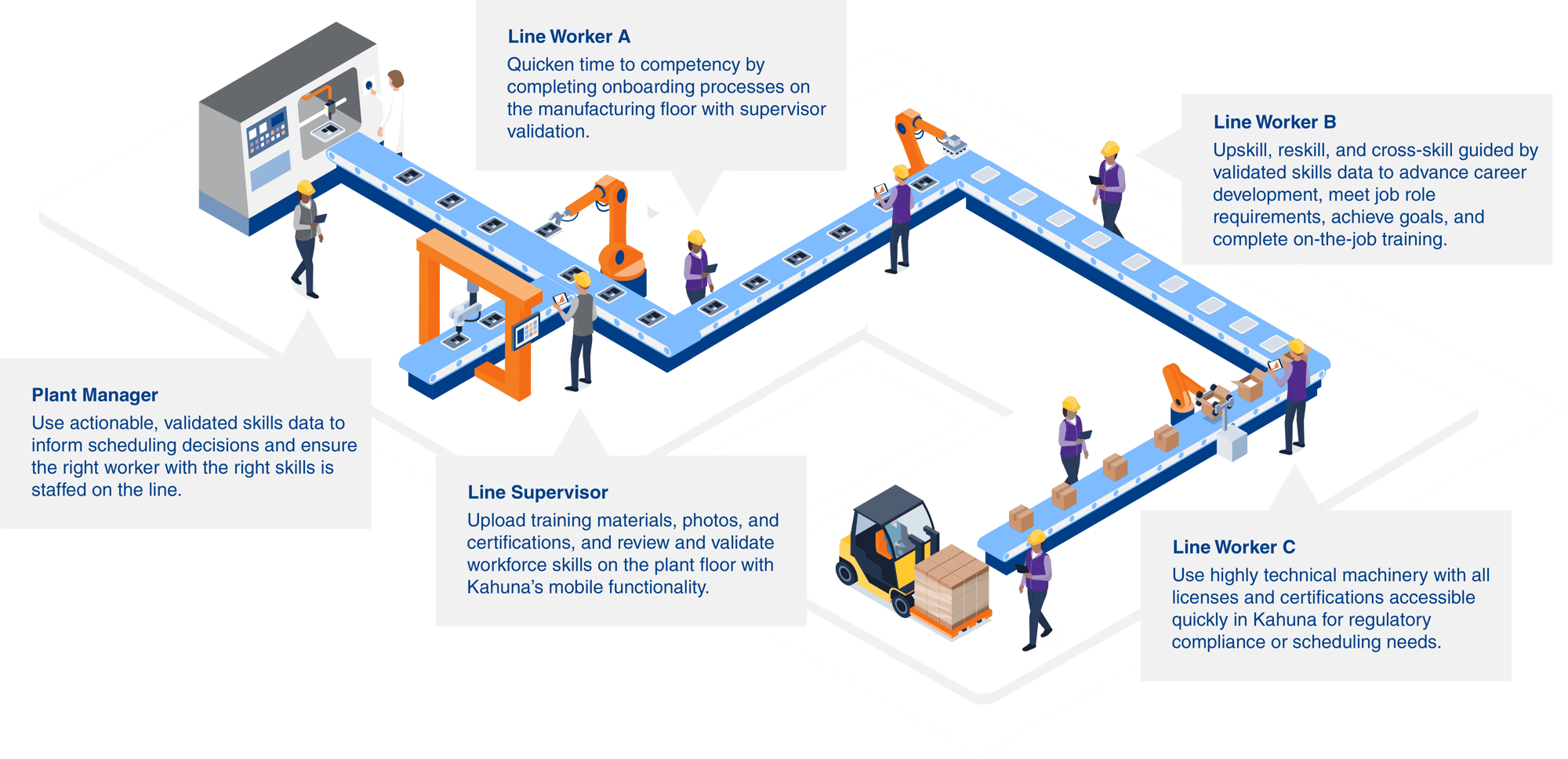

The Connected Worker: Tracking and Developing Skills on the Plant Floor

Much of employee onboarding and training is done on the plant floor for manufacturers. Kahuna enables individuals throughout the organization to use real-time skills data to ensure the workforce operates with the right skills at the right time, increasing productivity, safety, and quality.

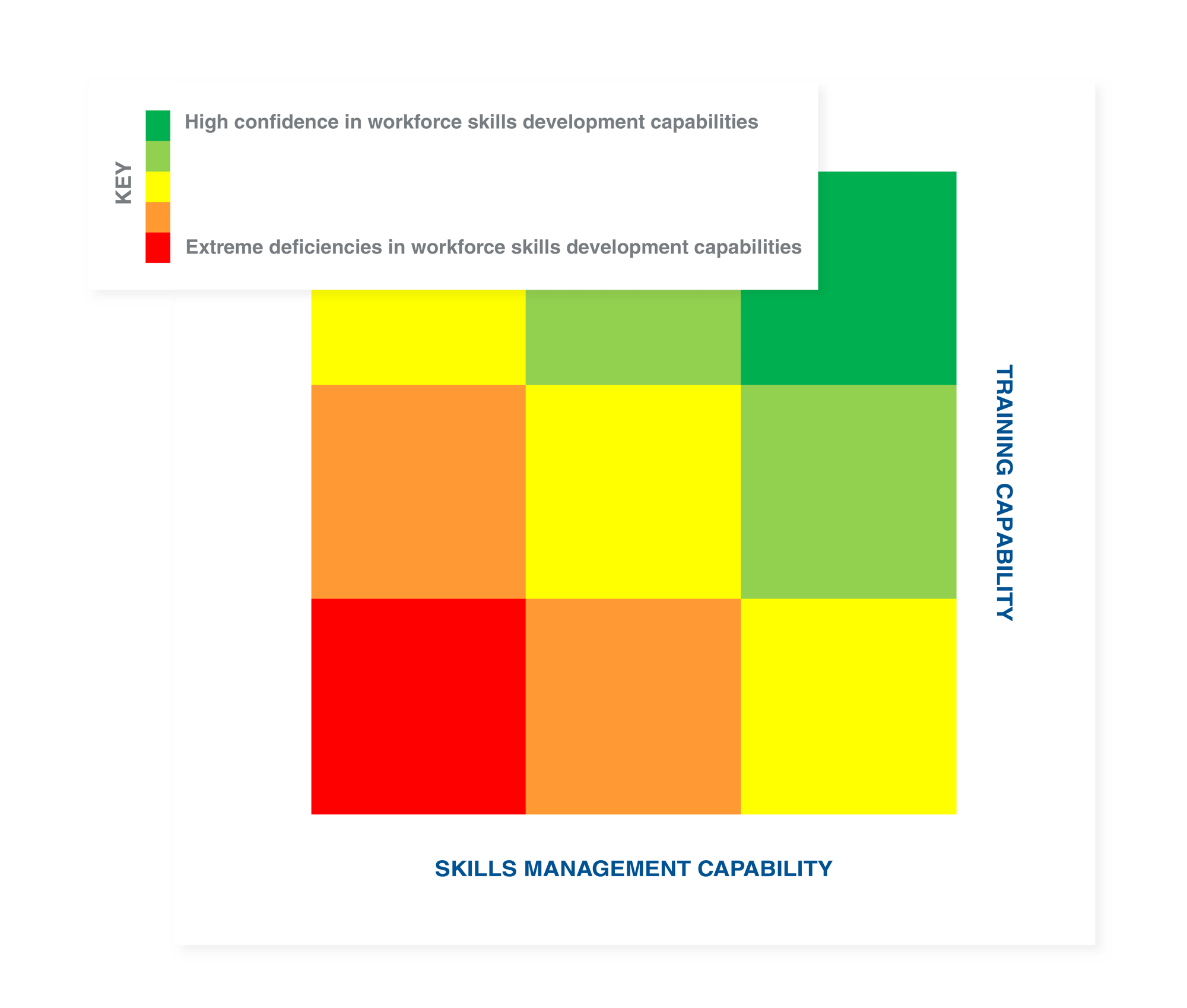

TRAINING MATRIXBuild Robust Manufacturing Training Programs Informed by Skills Data

As organizations look to tackle Industry 4.0 and Smart Manufacturing initiatives, they're promised higher efficiency, better flexibility, and increased profitability. But to enable these outcomes, a high-functioning training and development program is essential. Use Kahuna's skills and training capability matrix to determine organizational readiness for Smart Manufacturing initiatives.

Frequently Asked Questions About Manufacturing Skills Management

What is manufacturing skills and competency management?

Manufacturing skills and competency management is the business process of identifying critical skills, assessing organizational capability, and developing the workforce to meet dynamic industry demands and strategic business goals.

What are the benefits of skills and competency management in manufacturing?

Manufacturing skills management enables manufacturing organizations to meet fluctuating demand for talent, reduce and control cost of poor quality, minimize the threats of future disruptions, diminish risk and impacts associated with HSE incidents, and mitigate non-compliance risk.

What is effective training in manufacturing?

Effective training gives employees the knowledge, skills, experiences, and capabilities they need to perform their roles efficiently and in line with safety and quality standards.

How does skills management enable effective training?

Skills and competency management provides validated skills data to employees and managers at every level in the organization, from the factory floor to the C-Suite. These skill insights enable leaders to:

- Analyze and understand workforce skill gaps.

- Ensure a sufficient supply of qualified trainers.

- Access readily available training materials.

- Verify the knowledge and experience of employees.

- Plan for current and future disruptions with qualified and skilled teams.

What is Industry 4.0 or smart manufacturing?

Industry.4.0, also called smart manufacturing, is the advancement of technology and digital transformations within manufacturing. These advancements impact manufacturing processes and procedures, quality metrics, workforce skills, training and development needs, and more.

What are the benefits of Industry 4.0 in manufacturing?

Benefits of Industry 4.0 and smart manufacturing include:

- Higher efficiency and productivity with more streamlined supply chain operations, and seamless communication between digital systems and the personnel operating them.

- Better flexibility and agility through improved organizational and workforce capabilities, and competitive advantage.

- Increased profitability and lower costs associated with trade, transportation, and logistics, and new market growth opportunities.

TEMPLATE

Skills Management Sample RFP

Searching for the right manufacturing skills assessment platform can be tricky. Use our Skills Management RFP to efficiently create a software proposal and get answers to your most important questions.

.png?width=2000&height=1545&name=Smart%20Manufacturing%20Webinar%20-%20Pillar%20Page%20Image%20(1).png)